- Tests conducted for Cement

a)Field test

- when hand is inserted into the cement bag after opening it, it gives a cool feeling.

- moreover it gives a smooth feel , when a pinch of cement taken & felt between fingers.

- Take handful of cement & throw into bucket full of water, the cement particles starts floating & after sometime it starts to sink down .

B) Labortary tests

1) Fineness test

- Weigh 100g of cement & take onto the standard IS Sieve No.9 (90 microns).

- Break down the lumps present ,if any, with fingers.

- Sieve the sample for about 12-15 minutes (mechanical sieving can also be done)

- Weigh the weight of the residue left on sieve.

- Weight of residue should be less than 10%

Illustration Of Sieve Test:

Weight

of cement (before sieving) in gram

|

Weight

of sample (after sieving ) in gram

|

%difference

in weight

|

Remarks

|

100

|

7.8

|

7.8 %

|

Less than 10%

|

2) Standard Consistency test (Normal Consistency test)

- This test is used to determine the initial setting time , final setting time & soundness of cement

- This test is done by using “ Vicat Apparatus”

Procedure:

- Take 500 g cement & make paste by mixing it with water with different w/c ratios.Fill the sample in vicat mould within 3 -5 minutes i.e “gauging time. Attach a Standard plunger & allow it to dropdown by its self weight & penetrate into the cement paste.

- Repeat the process with different percentage of water in the ccement paste

- The percentage of water by weight of cement at which the plunger penetrated for a depth of 33-35mm from top is considered as the percentage of water required to make paste of standard consistency .it is denoted with “ P”

- Calculation of P

P= w/c *100

(where, w= quantity of water used &

c= quantity of cement used)

(NOTE: Least count of balance = 1g & measuring cylinder =1 ml)

General value of P for OPC lies between 24 to 31%

3) Setting time test

a) Initial setting

time

It is the time interval throughout which the

cement remains in plastic condition required for mixing,placing &

compacting.

Procedure:

- Take500g of cement & gauge it with water (0.85P)

- Fill the paste in mould & place it under the needle of the vicat apparatus.

- The time elapsed from the adding of water to the point where the needle penetrates the test block to a depth of 33-35 mm is noted.

- The time is the initial setting time.

- The minimum initial setting time should be minimum 30 mins

b) Final setting time

- It is the time at which the concrete looses its plasticity & start gaining strength.

- When the vicat needle is unable to pierce through the test block more than 0.5 mm.it is considered, it has attained its final setting time

- The maximum final setting time should not be more than 10 hours

4) Soundness test

- As presence of excess lime , magnesia & sulphates causes unsoundness of cement as they lead to undesirable expansion of set & hardened mass.Thus soundness test is the remedial measure to prevent the cause.

- Autoclave Test is performed for measuring soundness of cement, it indicates the presence of excess of both lime & magnesia ,unlike Le- Chatelier’s Test which indicates only presence of lime

Procedure:

- A cement specimen (25 x 25 mm) is placed in the standard autoclave & the steam pressure is raised to 21 kg/cm2 (gauge pressure) within 1 hour of turning on the heat.

- This pressure is maintained for next 3 hours.

- The autoclave is allowed to cooled & then the length of the specimen is measured again

- The % expansion of the specimen is found to be less than 0.8 %

Conclusion

Higher the expansion

of the specimen indicates the higher content of excess lime & magnesia

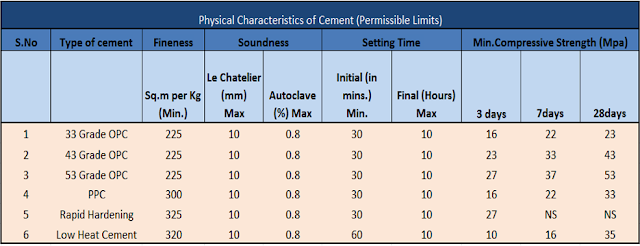

Physical Characteristics of Cement are mentioned in the Table:

Thanks for sharing more informative knowledge, I would like to share some more information regarding Best opc cement in india play a crucial role in the state's construction industry, providing high-quality cement for various building projects.

ReplyDeleteSkilled in fraud litigation. LosAngelesCivilLitigationLawyer.com

ReplyDeleteBOPP bags, crafted from high-quality Biaxially Oriented Polypropylene, offer unmatched strength, moisture resistance, and clarity, making them ideal for BOPP Cement Bags packaging a wide range of products—from food items to industrial goods. Their lightweight yet sturdy design ensures safe transportation while maintaining the freshness and quality of contents.

ReplyDelete